Technology

Ball Wave Inc.

- JP

- EN

Development story

Ball Wave is working on cutting-edge research and development using the principles of the ball SAW.

We asked the key personnel involved in research at the company about the behind-the-scenes stories, future possibilities, hopes, etc. for the various sensors.

Note: The content of material that was collected by an external agent on November 15, 2021 is introduced as the development history and behind-the-scenes story (masks were only removed while taking photos).

President & Chief Executive OfficerShingo Akao, Ph.D.

Chief Science Officer and Professor Emeritus of Tohoku UniversityKazushi Yamanaka, Ph.D.

Chief Operating OfficerNobuo Takeda, Ph.D.

Chief Strategy OfficerYusuke Tsukahara, Ph.D.

※今回はZoomにて対談に参加

Q1. Please tell us the development history and behind-the-scenes story for the ball SAW sensor.

Discovery of the properties of surface waves propagating along the equator (great circle) of the surface of a sphere

Yamanaka:The original beginning was research into “SAW filters” which are also used in mobile phones. SAW is an abbreviation of surface acoustic wave. The SAW filter is a device that has the function of sorting and individually allocating frequencies using the principles of SAWs. While we were pursuing research such as into the optimal materials for this device, we received a request from a ball-bearing manufacturer asking “is it possible to use surface waves to detect scratches (defects) on ball bearings?”. Through a lot of trial and error, we discovered a property of surface waves that they propagate while maintaining the same width when travelling along the equator (great circle) of the surface of a sphere.

Akao:This was a major discovery that destroyed the conventional knowledge in physics that “the spread of surface waves gradually attenuates as they propagate”. We thought that surface wave devices that originally had the purpose of being a filter could instead be used as sensors using this mechanism.

Yamanaka:The most easily understood example of the phenomenon of surface waves traveling around a sphere is the Earth. When an earthquake occurs, a phenomenon is actually observed by seismological stations where the seismic waves spread out, then collect again on the opposite side of the earth before spreading out again and returning. By applying this principle, it was found that when an inter digital transducer is arranged on the equator of a spherical piezoelectric body, the surface wave travels around repeatedly at the speed of sound. This is a “ball SAW sensor”.

Q2.Please tell us the development behind-the-scenes story, example applications, and future possibilities of the trace moisture analyzer.

There was originally no thought of creating a moisture analyzer

Takeda:We had been conducting research and development for gas chromatographs under the CREST program (Japan Science and Technology Agency), but the sensors we were using were impeded by moisture and we could not get good measurements no matter what we tried. We thought that we should try creating a moisture analyzer using the ball SAW sensor.

Akao:That’s right. As division head Takeda said, we did not originally have the idea of creating a moisture analyzer. Even though it is not part of the original research, questioning “something is strange” and thoroughly investigating led to the new discovery and breakthrough.

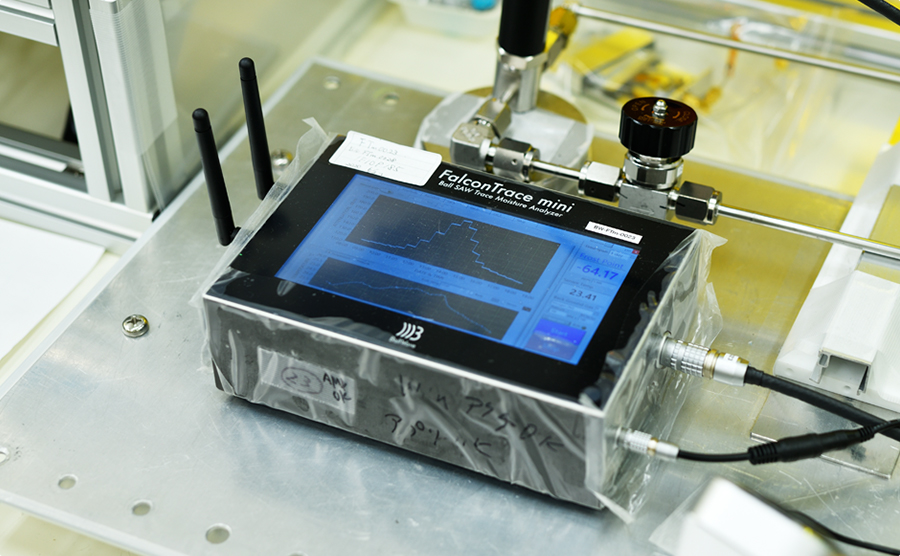

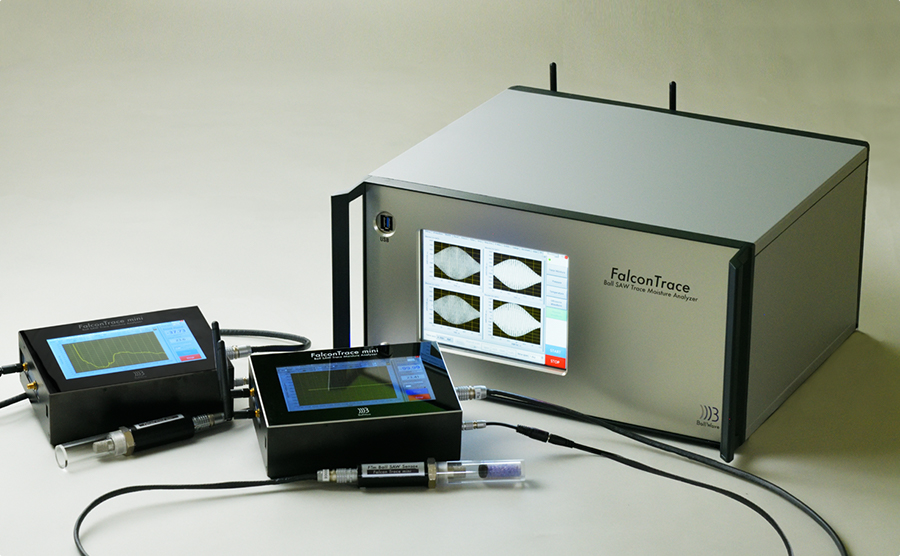

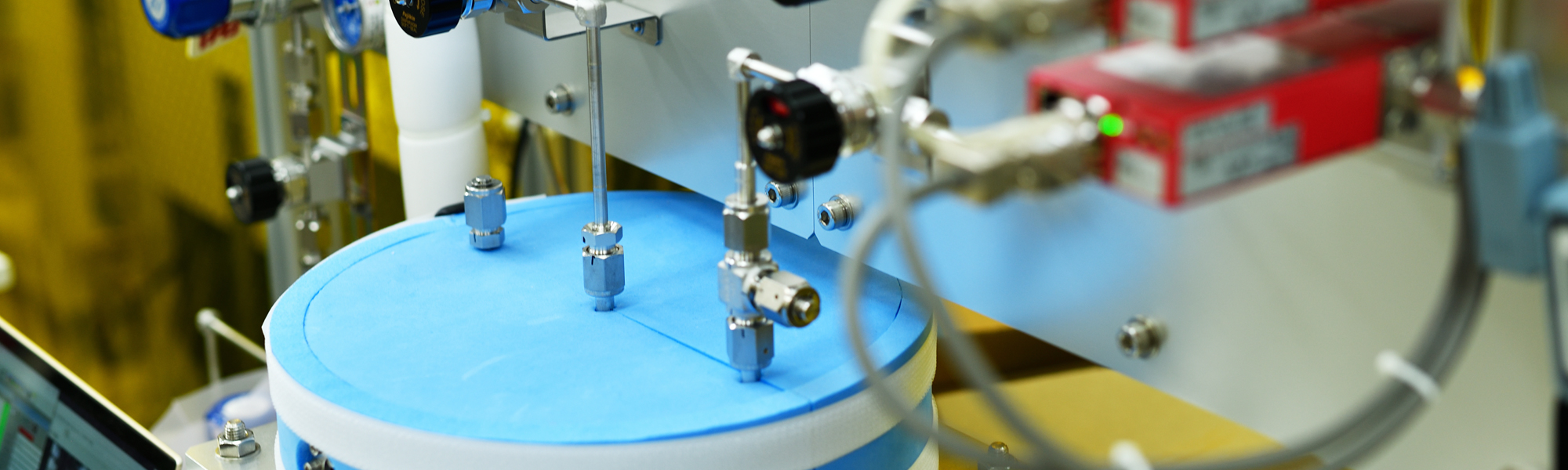

FalconTrace Trace Moisture Analyzer Series

Takeda:That’s right. In fact, this trace moisture analyzer is very useful in manufacturing processes that are averse to moisture. For example, contamination by water during the process of manufacturing semiconductor elements causes faults, and contamination by water during the manufacturing processes of lithium ion batteries such as used in vehicles shortens their life. When we say water here, this is not water as visible by the human eye, but ultra-trace amounts of moisture with air water concentration levels of 1 ppb (1 part per billion).

Tsukahara:For example, the wiring inside a smartphone is measured in units of nanometers. Since this is at the scale of one 10,000th or one 100,000th of a human hair, if there is water in the manufacturing process, it has an impact. The trace moisture analyzer is expected to become actively used in this kind of manufacturing field in the future.

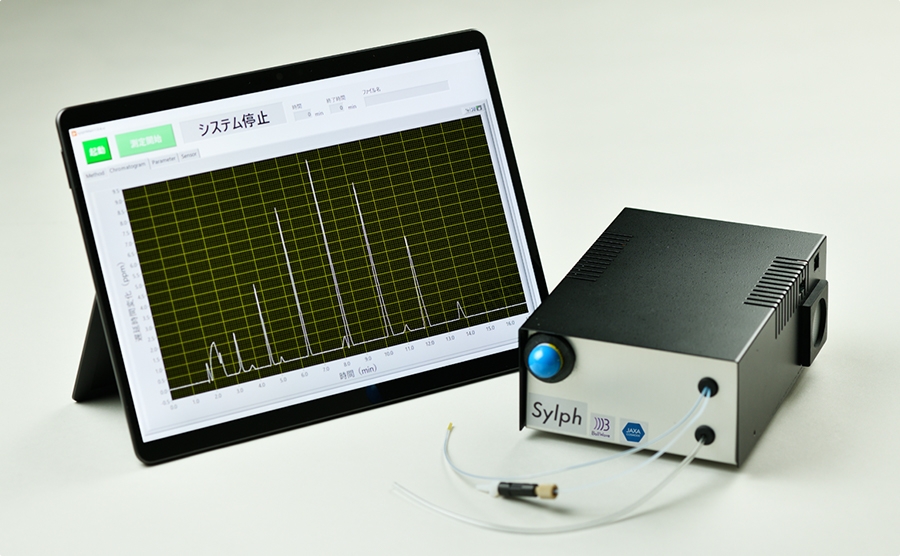

Q3. Please tell us the development behind-the-scenes story, example applications, and future possibilities of the portable gas chromatograph.

Need for lightweight compact gas chromatography

Yamanaka:The development of the portable gas chromatograph was the result of joint research with JAXA. Since there was a desire to mount analysis equipment on a rocket for exploration of Mars, but conventional equipment was too heavy, we worked on developing a lightweight compact gas chromatograph using the ball SAW sensor.

Takeda:A portable gas chromatograph for terrestrial applications was also developed in parallel with the development of the device for space. Although we are currently providing only a prototype, we are convinced that it will be used in a wide variety of fields.

Akao:We have recently had inquiries from companies such as food companies. A typical example is the need to explore the “most delicious timing” of fresh food. There has also been interest for use in quality management such as checking the progress of fermentation in fermented products such as Japanese sake, soy sauce, and wine.

Yamanaka:This can also be used for applications such as for detection of pollutants in soil and screening for harmful gases and abnormal odors. Since it is also able to detect gases produced by the human body, it may contribute to applications such as early detection of disease from exhaled air and intestinal gases.

Q4. Please tell us the development behind-the-scenes story of the ball SAW hydrogen sensor and the fields where it can be used.

Age of growing interest in and universal passion for hydrogen society

Akao:Actually, the first thing that we worked on was the hydrogen gas sensor. It was just exactly the time when interest in a hydrogen society was growing and everyone had become passionate about it. We recognized that hydrogen sensors were needed in hydrogen stations, and we thought that developing one would be useful for society.

Yamanaka:Although we progressed as far as a prototype product, hydrogen has not become as widespread in society as we had expected, and development of the sensor was temporarily placed on hold.

Takeda:That’s right. We have recently renewed research activity on the basis that the final product could be used by partner companies that are manufacturing hydrogen tanks for vehicles. Of course, we are still considering the original purpose of use in hydrogen stations.

Tsukahara:Furthermore, hydrogen sensors are also related to the problem of carbon neutrality, which is currently attracting attention. Although the idea of storing hydrogen generated from renewable energy has been raised, mainly in Europe, the hydrogen needs to be managed strictly for storage. Our hydrogen gas sensor is expected to be used for this.

Takeda:For the hydrogen gas sensor, we are at the stage of feeling out the two fields of the energy problem and vehicles.

Q5.Please tell us about the future possibilities for development extending from “ball SAW”.

There are many things that can be done with “ball SAW”

Yamanaka:Recently, with the spread of the novel coronavirus, progress has also been made in developing sensors for detecting viruses. Since it is possible to place an inactivated virus into a container and detect the substances that are generated, we eventually want to create a sensor that is able to detect viruses in the air.

Takeda:If viruses could be detected, it would also make it easier to trace infection routes. We expect that it would be used in a variety of locations, including airports and medical institutions.

Akao:We also have the idea of creating some kind of ball SAW plus a certain sensor that is not limited to merely “detecting something with the sensor”, but also creating some kind of added value to the data obtained from the sensor.

Yamanaka:However, our focus is still on the “ball SAW” part. Although we have been developing various things using the ball SAW sensor, initially the sensor itself was a single example application of a device using ball SAW. That is, although the sensor is certainly an important application, we feel that it does not need to be the limit.

Akao:That’s right. The reason for naming the company “Ball Wave” is because we are mainly focused on the principles of the ball SAW. By conducting research based on these principles, we may be able to create never-before-seen devices other than sensors.

Takeda: Since these four people are members of a quantum computing project, we may also be able to expand into that kind of field.

Tsukahara:There is also the possibility of creating new devices by using the ball SAW for controlling light and for communication.

Akao:“Ball SAW” can do many things with both small and large themes. Moving forward, we would like to pursue research and development that is not limited to existing ideas but aims for creation of new value.

Note: The content of material that was collected by an external agent on November 15, 2021 is introduced as the development history and behind-the-scenes story (masks were only removed while taking photos).